PLASTIC INJECTION

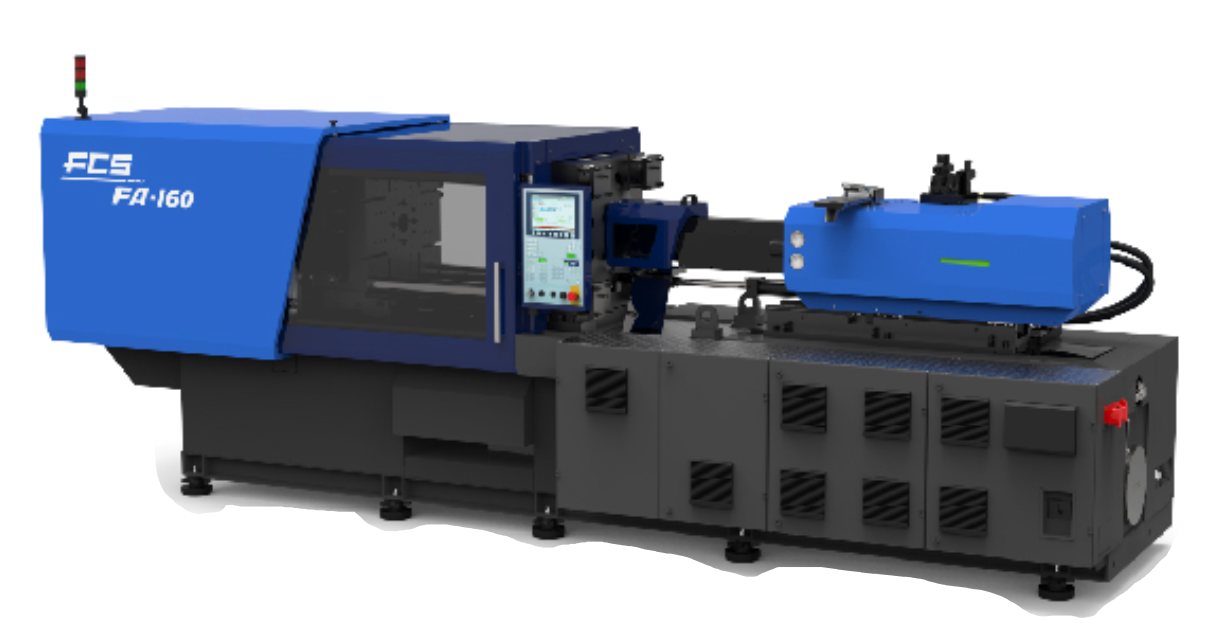

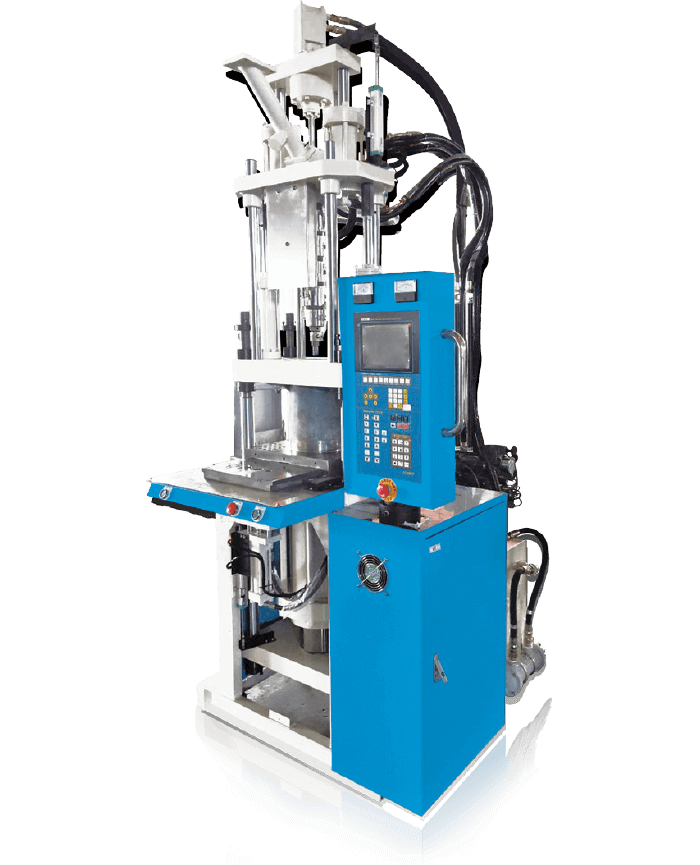

From 90 TON to 300 TON, our horizontal and vertical injection molding machines, equipt with electric adjustment robots, perform seemless services for our customers.

From 90 TON to 300 TON, our horizontal and vertical injection molding machines, equipt with electric adjustment robots, perform seemless services for our customers.

The mold is the quality origin of plastic injection molded parts, We have a mold department that designs and repairs our molds. We maintain our injection molds regularly to increase mold life, and to maintain stable product quality.

We have introduced modern computer control and an automatic material feeding system. This prevents overheating and controls the material mixture. Furthermore, JUMPWAY has implemented robots to increase production efficiency and maintain stable quality. This allows us to further reduce production cost and improve cost effectiveness.

To satisfy our customer’s need for diversified product, we have Mold Heaters, Hot Runner Controllers, Dehumidifying Dryers, and High Frequency Machines. JUMP WAY is 100% certain we can satisfy our customer’s demands for quality of injection products.

Currently the plastic parts we supply to our customers include automobile parts, electronic parts, electrical appliance parts and more.

Hover over each machine for more information about them.

(FA-160) Fu Chun Shin ... machine, likely going into detail on machine type. Perhaps even a table of the TON codes available.

Fu Chun Shin... this machine, likely going into detail on machine type. Perhaps even a table of the TON codes available.

Generic information regarding this machine, likely going into detail on machine type. Perhaps even a table of the TON codes available.

D255,D305 Generic information regarding this machine, likely going into detail on machine type. Perhaps even a table of the

Generic information regarding this machine, likely going into detail on machine type. Perhaps even a table of the TON codes available. Computerized.

HT-200SV, HT-125SV, HT-100SV Generic information regarding this machine, likely going into detail on machine type. Perhaps even a table of the TON codes available.